“SDS did what they do best – they replaced the non-operational unit. The replacement unit was in stock, and hand delivered, so we did not have to wait for our resolve. I would definitely call on SDS again for any engineering support, future upgrades and for the procurement of critical parts’.

The Situation

They are recognised as an established manufacturer of trade extruded products, specialising in the design & development of new and bespoke profiles to meet specific customer requirements.

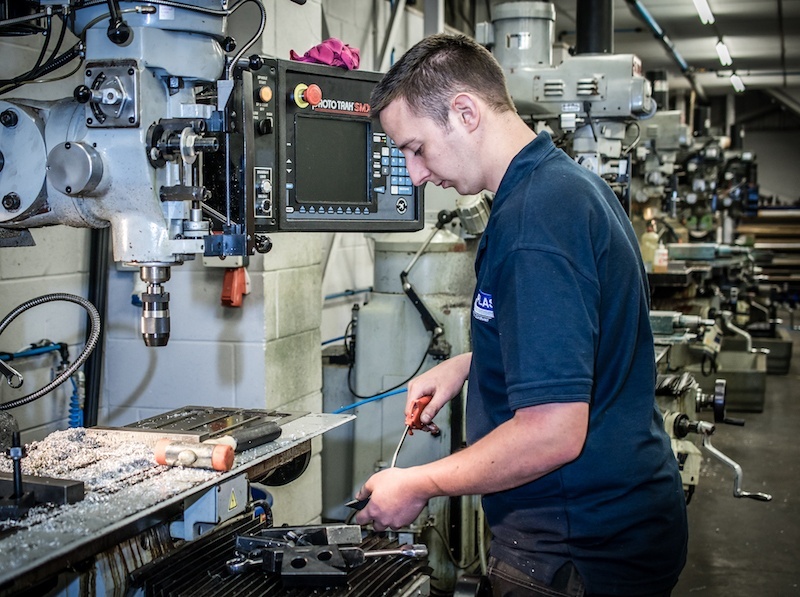

Nenplas have been a client of SDS for quite some time. For our most recent project, our engineer attended Nenplas’ Ashbourne site to replace a faulty non- Parker unit in the screw feeder machine. To do this, we had to explore the existing wiring and produce a drawing of this to mirror and match the soon-to-be-installed new Parker unit.

Due to the nature of the environment, there was lots of movement – such as pedestrians and forklifts, which meant we had to be more vigilant with the task in hand.

The Solution

Our engineer refitted a Parker unit, which meant that the old unit had to be removed beforehand, then the wiring and slight re-wiring was completed, which took a full working day due to the environment of the site.

Benefits